As described by eTrailer.com

DETERMINING TRAILER TONGUE WEIGHT

In order to make sure your trailer is properly loaded, you need to know your trailer tongue weight. Tongue weight is the weight that the fully loaded trailer exerts downward on the hitch ball of the tow vehicle. Typically, your tongue weight should be 10-15% of your total trailer weight. If you don’t know the tongue weight of your trailer, there are several different ways you can measure it.How to measure tongue weight:

- Tongue Weight Scale

- Bathroom Scale

- Commercial Scale

Curt BetterWeigh Tongue Weight Scale

Tongue Weight Scales

The easiest way to measure your tongue weight is with a tongue weight scale. Various scales are available to help you easily and accurately measure your trailer’s tongue weight. We’ll talk about the most common scale tools below.

Curt BetterWeigh

Tongue weight scales have come a long way into the modern world. For instance, Curt’s BetterWeigh wirelessly connects to your smartphone and allows you to easily measure your tongue weight, pin weight, payload, and gross combined weight—all right from your phone. The weight distribution feature lets you verify your weight distribution system is set up properly. The BetterWeigh works on both travel trailers as well as fifth wheels and gooseneck trailers.

HaulGauge Mobile Tongue Weight Scale

Sherline Scale

Another popular tool is the Sherline Trailer Tongue Weight Scale. The Sherline Scale can be used with standard trailers as well as fifth-wheel campers with tongue weights up to 2,000 lbs. Simply place the scale beneath your trailer jack on level ground, and the easy-to-read gauge will display your tongue weight.SHOP NOW

Weigh Safe Ball Mount

Weigh Safe Ball Mount

A third option is a Weigh Safe ball mount with a built-in tongue weight scale. Weigh Safe ball mounts are adjustable and are available in various sizes, rises, and drops. With a Weigh Safe ball mount, there’s no need to keep track of or store a separate scale.

etrailer Tongue Weight Scale

etrailer Tongue Weight Scale

The etrailer Tongue Weight scale is another alternative for measuring your trailer’s tongue weight and ensuring you’re not overloaded before you head off on your next adventure. The heavy steel footplate grounds the scale for an accurate assessment.

Bathroom Scale

You can use a bathroom scale and a box to measure tongue weight of smaller trailers. Place the coupler of the loaded trailer on the scale at normal towing height (see Figure A). For heavier tongue weights, use the second method (Figure B). Be sure to perform these measurements on a level surface and with a leveled trailer.

To use the method in Figure B, follow these guidelines:

- Place the trailer tongue 1 ft from the pipe on the support brick

- Multiply the reading on the scale by the total distance between the 2 support pipes

- Use a brick that is the same thickness as the scale so that the 2 x 4 is level when you weigh your trailer

Example: If the distance between the trailer tongue and the pipe on the scale is 2 ft, and the distance between the trailer tongue and the pipe on the support brick is 1 ft, then multiply the reading on the scale by 3 to get the tongue weight. If the distance between the trailer tongue and the pipe on the scale is 3 ft and the distance between the trailer tongue and the pipe on the support brick is 1 ft, then multiply the reading on the scale by 4 to get the tongue weight.

Commercial Truck Scales

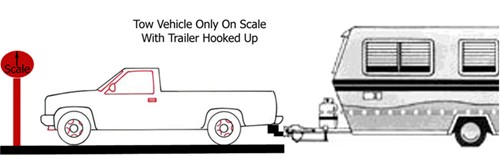

Another way to determine your trailer’s tongue weight (and get your vehicle and trailer weights) is to take the trailer with your tow vehicle to a scale at a truck stop, quarry or material supply center. For a small fee, you can weigh your tow vehicle and trailer there.Step 1: Determine Weight of Vehicle with Tongue WeightYour vehicle and trailer must be fully loaded and fueled just as they will be when you are leaving for a trip. First, drive on to the scale with all 4 wheels of the truck and record the weight of the truck with the trailer attached.

Pictured: Commercial truck scaleStep 2: Determine Weight of Vehicle without Tongue WeightUnhook the trailer and jack up the trailer tongue so there is no weight on the hitch ball. Make sure that the trailer jack is not on the scale. Record the weight of only the truck on the scale. This is your gross vehicle weight (GVW). Now, subtract the GVW from the weight of the truck with the trailer attached. This will give you the tongue weight of your trailer.A – B = Tongue Weight

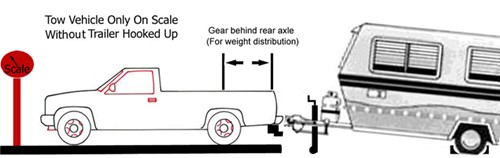

Determine Tongue Weight for Weight Distribution Hitch

If you want to use a weight distribution hitch, remember to include the weight of any gear you might load behind the rear axle of the tow vehicle. You should add the weight of this gear to your tongue weight to select a weight distribution system of the proper size.

Step 1: To get the weight of the gear behind the rear axle, weigh your vehicle with this gear and without. Then subtract the weight without the gear from the weight with the gear. This difference is the weight of your gear. A – B = C. Ex: (A) Vehicle weight with gear behind rear axle – (B) vehicle weight without gear behind rear axle = (C) total weight of your gear Step 2: Add the total weight of your gear to your tongue weight. Your weight distribution hitch must support this weight. Ex: 200 lbs. (total weight of gear) + 800 lbs. (TW) = 1,000 lbs. (weight distribution must support this weight)Learn more about finding the right weight distribution hitch size here.

Determine Additional Weights

While you are at the scale, you can also make sure that your towing setup is within the rated capacity of your tow vehicle. To do this, you need to get the weight of your trailer.To weigh your trailer, pull it with your tow vehicle onto the scale so you can weigh them together. This weight is your Gross Combined Vehicle Weight (GCVW). You can get the weight of your trailer (Gross Trailer Weight – GTW) by subtracting the weight of your tow vehicle alone from the weight of your tow vehicle and trailer combined (GCVW).Then, check your owner’s manual or with your dealer to determine if the weight of your trailer is within the towing capacity of your tow vehicle.GCVW – GVW = GTW(Tow vehicle + trailer) – (tow vehicle) = trailer weight

Related Articles2 Steps for Finding the Right Weight Distribution Hitch SizeHow to Measure for Trailer Hitch DropConfidently Choose Your Weight Distribution Hitch – Here’s 5 Tips Related Products Shop Tongue Weight ScalesShop Ball MountsShop Weight Distribution

HOW TO CHOOSE THE RIGHT SIZE TRAILER HITCH:

Which Class of Trailer Hitch is Best Suited for You?

If you’ve never dealt with trailer hitches before, it can be kind of confusing. What do the different classes mean? What sizes are there, and what size do you need? The hitch class and receiver size you need depends on two factors: what you want to tow or carry, and what your vehicle can handle. (You can put the strongest hitch in the world on the back of a Ford Focus, but you’re still not going to transform your Focus into a trailer-towing giant!)The quickest and easiest way to figure out which hitches will work for your vehicle is to use our fit guide. Just input your vehicle’s year, make, and model, and we’ll show you only the hitches that fit. But what if multiple hitch classes or sizes turn up, and you have options? What trailer hitch class do you need then? We’ll go over hitch classes in more detail below, so you can confidently make the choice best suited for your vehicle and towing situation. Looking for a custom fit?

See trailer hitches confirmed to fit your vehicle.

What are the Different Trailer Hitch Classes?

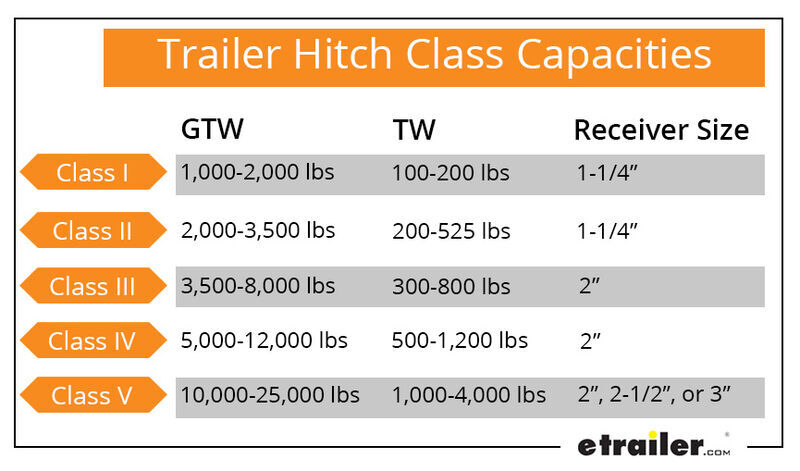

There are a total of 5 trailer hitch classes, with Class I having the lowest capacity and Class V having the highest. Hitch classes essentially designate the hitch opening size and weight capacity. Here’s a quick breakdown of the 5 hitch classes, their associated capacities, and their typical receiver sizes.

Okay, great, you may be thinking. But what do these numbers actually translate to? For context, we’ve broken out the 5 trailer hitch classes below, including the typical tow vehicles, trailers, and accessories you’ll see associated with each size. Keep in mind that you are always limited by your lowest rated component. For instance, if your hitch can haul 8,000 lbs. but your vehicle can only haul 3,000 lbs, you’re maxed out at 3K.*You can also check out our Tips on How to Tow a Trailer article as well as our Determining Trailer Tongue Weight article for more help towing your trailer!

KEY TERMS

- Gross Trailer Weight (GTW): Weight of the loaded trailer. To determine GTW, weigh the loaded trailer on a vehicle scale.

- Tongue Weight (TW): The downward pressure placed on the ball by the coupler. To determine TW, use a tongue weight scale or other method described here.

What is a Class I Trailer Hitch?

A Class I trailer hitch is the lightweight champion of the 5 available classes, making it perfect for small loads like kayaks or cargo carriers. These hitches are most often found on passenger cars and smaller SUVs. Class I and Class II trailer hitches typically have a 1-1/4″ x 1-1/4″ receiver opening. Class II accessories will not work with Class I hitches. Max GTW: 1,000-2,000 lbs. Max TW: 100-200 lbs. Receiver opening: 1-1/4″

Class I Typical Loads

-

- Bikes (max 2)

- Cargo carriers

- Kayaks

- Canoes

- Mobility scooters

- Small trailers

Class I Typical Tow Vehicles

-

- Compact cars

- Midsize cars

- Full-size cars

- SUVs

- Minivans

What is a Class II Trailer Hitch?

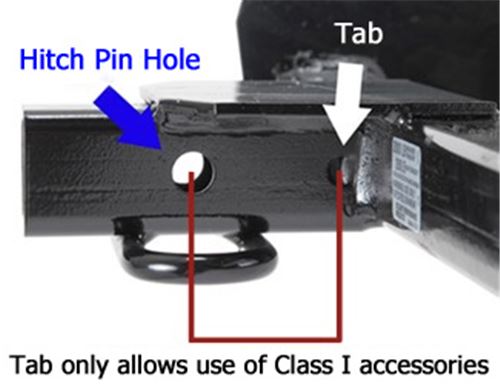

A Class II trailer hitch is just a bit heftier than a Class I hitch. Like Class I hitches, they are typically found on passenger cars and smaller SUVs. Because Class I and Class II hitch receivers are usually the same size, many people wonder if their Class II accessories will fit their Class I hitch. But alas, this is not the case! Class I hitch receivers have a built-in stopper so that drawbars and accessory shanks can only slide into the trailer hitch opening to a certain point. Class II accessories have a longer shank, so they’ll run into the stopper and won’t be able to slide all the way into the receiver. This is to keep you from accidentally overloading your Class I hitch with a heavier Class II accessory. On the other hand, you CAN use a Class I accessory in a Class II hitch. Max GTW: 2,000-3,500 lbs. Max TW: 200-525 lbs. Receiver opening: 1-1/4″

Class II Typical Loads

-

- Bikes

- Cargo carriers

- Kayaks

- Canoes

- Mobility scooters

- Small trailers

- Small pop-up campers

- Small boats

Class II Typical Tow Vehicles

-

- Compact cars

- Midsize cars

- Full-size cars

- SUVs

- Minivans

What is a Class III Trailer Hitch?

Class III hitches are some of the most common due to their wide range of weight capacities (about 3,500 lbs. GTW to 8,000 lbs. GTW). If you want to tow a camper, you’re best off sticking with at least a Class III hitch. Since this is the most common hitch size, you have way more options for everything from trailers to bike racks to cargo carriers. Class III hitches have 2″ x 2″ wide receiver openings. However, you can still use 1-1/4″ accessories if you’ve got them by using an adapter. Max GTW: 3,500-8,000 lbs. Max TW: 300-800 lbs. Receiver opening: 2″

Class III Typical Loads

-

- Midsize campers

- Utility trailers

- Lawn maintenance equipment

- Bikes

- Cargo carriers

- Kayaks

- Canoes

- Motorcycles

- Snowmobiles

Class III Typical Tow Vehicles

-

- Full-size cars

- Large SUVs

- Minivans

- Trucks

- Heavy-duty trucks

What is a Class IV Trailer Hitch?

We again step up the weight capacities with Class IV hitches. Like Class III hitches, Class IV hitches typically have 2″ x 2″ receivers. However, they come with an even beefier weight capacity (up to 12,000 lbs. GTW).Class IV hitches have 2″ x 2″ wide receiver openings. However, if you want to use your 1-1/4″ accessories with your 2″ hitch, you can use an adapter. Max GTW: 5,000-12,000 lbs. Max TW: 500-1,200 lbs. Receiver opening: 2″Class IV Typical Loads

- Large campers

- Large boats

- Toy haulers

- Horse trailers

Class IV Typical Tow Vehicles

-

- Heavy-duty trucks

- Large SUVs

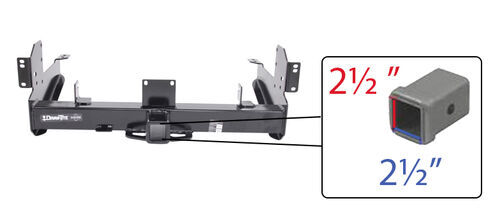

What is a Class V Trailer Hitch?

Class V trailer hitches are as big as they come. These are the heavy-duty hitches made for hauling your heaviest trailers and toy haulers. Most Class V hitch receivers have a 2-1/2″ receiver opening, although some have a 2″ opening, and the largest even have a 3″ opening (these giants are welded to the tow vehicle’s frame).If you need to carry a smaller accessory with a Class V hitch, adapters are available. (Special shout-out to our B&W adapters, which are designed with pinched ends to make lining up your pin holes effortless.)Max GTW: 10,000-25,000 lbs. Max TW: 1,000-4,000 lbs. Receiver opening: 2″, 2-1/2″, or 3″Class V Typical Loads

-

- Large toy haulers

- Equipment haulers

- Multi-car trailers

- Horse trailers

Class V Typical Tow Vehicles

-

- Heavy-duty trucks

- Commercial trucks

Still have questions? Give our experts at eTrailer.com a call at 800-298-8924, or contact us online. We’re happy to assist any way we can!

WEIGHT DISTRIBUTION HITCH

If your trailer’s swaying has you white-knuckling the wheel, if steering and stopping your rig is a harrowing experience, or if your tow vehicle’s headlights are pointed toward the sky, you probably need a weight distribution hitch. A weight distribution hitch (or weight distribution system) helps to ensure a smooth, level ride and allows you to tow at the maximum capacity allowed by your hitch. It also helps to correct tow vehicle sag, improve steering and stopping, and—when used with sway control—correct trailer sway. Read on to Learn:

What is a Weight Distribution Hitch, and How Does It Work?

When Do You Need a Weight Distribution Hitch?

Does a Weight Distribution Hitch Increase Towing Capacity?

Can Weight Distribution Be Used with Surge Brakes?

What Are the Components of a Weight Distribution System?

A weight distribution hitch is a system designed to create a level, stable ride when you tow a trailer. Basically, a weight distribution hitch will help keep your towing setup level and make sure the weight of your trailer doesn’t cause undue stress on your vehicle.

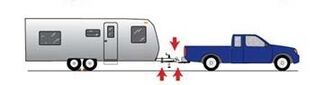

Without a weight distribution hitch: the additional weight of the trailer on the vehicle’s rear axle causes the vehicle’s back end to sag and the front end to point upward.

What Happens to Your Vehicle When you Tow a Trailer?

To understand why a weight distribution hitch works, it’s important to understand what happens to your vehicle when you tow a heavy trailer behind it. When you tow a trailer with a standard, rear-mounted hitch, your trailer’s tongue weight is transferred to the rear axle of your tow vehicle. This can weigh down your vehicle’s back end and cause the front end to point upward, especially on vehicles that have suspension designed for everyday comfort.If this happens, your vehicle’s rear axle will bear the weight of not only the trailer, but much of your tow vehicle’s weight as well. What’s more, the lessened weight on the vehicle’s front axle can diminish your steering, traction, and stopping power. Your view of the road may be limited due to the awkward angle, and you may experience increased trailer sway.

Your tow vehicle’s owner’s manual should provide you with tow weight specifications and information regarding weight distribution use. For instance, the 2018 Chevy Traverse owner’s manual states that weight distribution and sway control are required when towing a trailer over 5,000 lbs. For safety and liability reasons, you should always comply with manufacturer instructions. If you choose not to, and a problem arises, your insurance company may not be there to help (especially for a commercial business) since you chose to ignore manufacturer recommendations. Even if you are within the towing limits set by your equipment, vehicle manufacturer, etc., there are other indicators that you may benefit from a weight distribution hitch, including:

- Your trailer weight (GTW) is more than 50% of your vehicle’s weight (GVWR)

- The rear of your tow vehicle sags when the trailer is hooked up

- You experience trailer sway

- Your tow vehicle’s headlights point upward

- You find it difficult to steer or stop your rig

- You want to tow to the highest capacity allowed by your trailer hitch

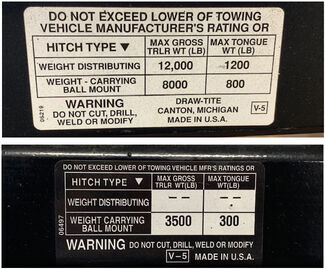

Weight Distribution vs Airbags: The recommendation is as follows: Vehicle sag due to load in the truck bed: airbags Vehicle sag due to trailer connection: weight distribution

If your hitch is rated for use with weight distribution, the weight distribution system will allow you to tow at the maximum capacity of the hitch. Weight distribution doesn’t “increase” your hitch’s capacity so much as it allows the hitch to be used at its maximum capacity. Check the hitch’s ratings to determine your towing capacity with and without weight distribution. Note that only designated Class III, IV, or V hitches may be used with weight distribution systems. You should also note that a weight distribution system does not increase the towing capacity of your vehicle. Your towing system will only be as strong as its lowest-rated component. You should always abide by the stated towing capacities of your vehicle and towing equipment. Failure to do so can result in equipment damage or failure. Keep in mind that not all hitches are designed for use with weight distribution systems. Always check the trailer hitch’s weight rating label for a weight distribution towing capacity. If there is no such capacity listed, then a weight distribution system cannot be used.

Example: The top sticker indicates that a weight distribution hitch may be used. Using weight distribution will allow you to tow up to 12,000 lbs rather than 8,000 lbs. The bottom label indicates that a weight distribution hitch may not be used.

Only specified weight distribution hitches can be used with surge brakes. Most chain-style systems are not compatible with surge brakes as they do not allow for enough back and forth movement of the trailer to activate the actuator. Some manufacturers have rated their chain-style weight distribution systems as surge brake compatible, but you should note that adding friction sway control bars to these systems will make the system incompatible with surge brakes. To make sure your brakes operate at maximum effectiveness and are not prevented from compressing, it is recommended that you do not use a chain/snap-up bracket system with your surge brakes. You can shop for weight distribution hitches compatible with surge brakes. You can also browse systems compatible with electric brakes.

What Are the Components of a Weight Distribution System?

A weight distribution system requires 5 main components in order to operate:

-

- Class III, IV, or V trailer hitch receiver rated for use with weight distribution

- Weight distribution shank (slides into trailer hitch)

- Weight distribution head assembly

- Spring bars

- Frame brackets

1. Trailer Hitch Receiver

The trailer hitch receiver attaches to the frame of your vehicle and provides the receiver opening that the weight distribution shank slides into.

2. Weight Distribution Shank

The weight distribution shank slides into your trailer hitch receiver and provides an attachment point for the weight distribution head assembly. Shanks are available in many lengths, drops, and rises to ensure your trailer is level with your vehicle. You can purchase a weight distribution hitch with a shank, or you can purchase a hitch without a shank and purchase the shank separately. Purchasing a shank separately would

be a better choice, for instance, if you require a greater rise or drop than provided by the standard shank included in the kit. For more on finding your hitch rise or drop, check out our article here.

3. Weight Distribution Head Assembly

The head assembly type will differ between systems, so most won’t look exactly alike. However, all head assemblies will attach to the weight distribution shank, provide a place to mount the hitch ball for trailer hookup, and provide the spring bar attachment point. The head assembly will also be used to fine-tune the amount of leverage applied to the system. Many standard head assemblies have built-in platforms for mounting friction sway control bars. Friction sway control bars mount to a smaller ball on the side of the weight distribution head. Some heads only have ball holes for a right-side attachment. Others, like those pictured below, have dual platforms so that you can mount a sway control bar on either side (or both sides) of your trailer. Many premium systems also feature sway control points in the head assembly itself for the most stable ride.

Weight distribution head assembly

Weight distribution head assembly with hitch ball and spring bars attached

Weight distribution head assembly with dual sway control attachment points

4. Spring Bars

Spring bars apply leverage to your towing setup, thereby distributing the load on the rear of your vehicle to all the axles on your tow vehicle and trailer. Spring bars come in round, trunnion, and square shapes. Check out our article, Confidently Choose Your Weight Distribution Hitch – Here’s 5 Tips , for help on choosing between them.

5. Frame Brackets

Frame brackets mount to the frame of your trailer and are used to hold the spring bars in place. Various types of bracket designs are available. Standard weight distribution systems use a bracket and chain system to secure the spring bars to the trailer. However, many higher-end systems have specially designed sway-control brackets for additional trailer control.

Standard snap-up bracket

Friction sway control bracket